INBT's International Research Experience for Students (IRES) program immerses students in bioengineering research projects at IMEC in in Leuven, Belgium. The goal is to cultivate their perceptions of global challenges in STEM, learn how to collaborate with international partners, and develop their research skills.

Tuesday, June 30, 2015

"I can turn a three into a heart!"

It’s difficult to believe that we’ve been here for almost a month already! Now that we’ve really settled into a routine at work, the days simply fly by - suddenly it’s almost 5:30 and you wonder where the day went, lost in culture rooms and in front of microscopes.

This week I started work on a new project, one that focuses on a more efficient way of testing clinical drugs on cardiomyocytes (heart muscle cells). Traditional culture of cardiomyocytes uses big disorganised clusters, which don’t resemble the linear arrangement of cells in an actual heart. Because of this, a significant number of drugs are pulled from the market due to heart issues that weren’t seen in clinical trials. Using a chip designed with alternating lines of hydrophobic (water-resistant) and hydrophilic (‘water-loving’, where cells attach) areas, we’re trying to get the heart cells to grow in single-cell lines to mimic their real-life organisation. There’s plenty of work to be done - because these procedures are still fairly early on, we’re testing all different cell densities, materials to seed the cells on, sterilisation methods, and line designs to see which one gives us the best results!

One of the most comedic moments for me was when I was first introduced to the designs we used that had cells attached. Above each pattern of lines is a number to distinguish which pattern it is, which also becomes hydrophilic during the preparation of the chips. As we prepared the samples for the microscope, my supervisor grinned and said, “Want to see something cool? I can turn a 3 into a heart!” And as I looked into the microscope, there it was indeed - heart cells arranged in a perfect number 3, happily beating away!

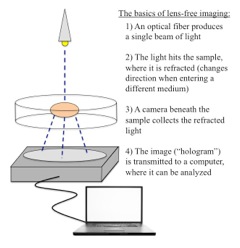

When we go to actually test the cells, we make use of a lens-free imaging setup. The advantage of this over a traditional microscope is that we get a much wider range of view, and it’s much simpler - instead of needing a big nosepiece and all the different lenses, all we need to do is put a laser source above our sample and a camera below, and hook it up to a laptop. (See the image for a bit more description of what goes on!) Once we collect a few seconds of images of the cells beating, we can adjust the images to yield a time-lapse that shows the propagation of the contraction of the cells as they beat, which looks like a wave rolling across the screen. After studying extensively the mechanics of how the signals are conveyed between cells to cause them to contract this year, seeing it in real life with data we’d collected was incredible!

Outside of work, I’ve made it my mission to try every chocolatier and café in Leuven during my time here, and I have to say that I haven’t been disappointed! I’ve taken trips up to London to visit my boyfriend for a weekend and to Bruges, which is an absolutely gorgeous (if very touristy) town. In Bruges, we visited St. John’s Hospital, which has a big museum with the tools of doctors from its time - all I can say is thank goodness medicine has advanced since the 11th century!

Each week here just gets better and better as I get more into my work, and I’m loving the project that I’m working on!

---Becca Black

Time flies when you are having lab fun

It's crazy how fast time flies. Three weeks have passed and whenever I look at my calender, I’m shocked to see that I’m almost halfway done with my stay here in Europe!

On a work-related note, I've now officially trained for all the biolabs and equipment I have to use and - after several days of not getting the experiment to run - I've gotten pretty good results and data! Right now, I'm focusing on increasing the efficiency of the surface coatings of the micro-channels so I've been in the lab, constantly coating new devices and running experiments. But, working in the lab is fun - more so than sitting in an office cubicle all day.

This past weekend, I went to Antwerp with Gwen, and it was beautiful! I loved being able to relax and walk along the river, then go straight into the shopping district. One thing that was awesome to see was MOMU, a fashion museum for Belgian designers, which isn't something I get to see often.

I lost my all my keys on the train, leaving me temporarily homeless (well, actually I was just staying in the room across from mine. I just didn't have any of my things), but fortunately someone turned them into Leuven Station so I was able to pick them up on Monday. Lesson learned: always check if I have my keys, wallet, and phone before leaving the train.

I lost my all my keys on the train, leaving me temporarily homeless (well, actually I was just staying in the room across from mine. I just didn't have any of my things), but fortunately someone turned them into Leuven Station so I was able to pick them up on Monday. Lesson learned: always check if I have my keys, wallet, and phone before leaving the train.I'm planning a lot more trips the following weekends until I get back home so I'll definitely be updating as I go along.

---Rachel Bang

Thursday, June 25, 2015

Suit Up

|

Figure 1: (http://quotesblog.net/amazed-reactions-gifs/)

|

You know that moment in the movies where the protagonist

sees something really amazing? The shot gets really wide and you just see the

main character standing there with their silhouette and everything they see in

front of them? It’s a surprise, a pleasant one that kind of takes their breath

away at least for a moment. Well, that’s how I felt as Evelien Mathieu, my

supervisor, lead me through the labs in imec.

It sounds corny, I know, but after two days of delays in

Newark Liberty Airport I started to get nervous about the prospect of spending

10 weeks in Leuven. I felt like maybe these thunderstorms and flight

cancellations were foreshadowing. So when I actually arrived, about 48 hours

late, everything seemed to look better.

Initially my time at imec started off slow; adapting to the

work environment, learning which floors led to the neuroelectronics lab and

which ones led to the warehouse, taking safety training. Then the real work

began. We started working on a project that combines lens free imaging and cell

migration in microfluidic devices. It consists of three big steps: 1.

fabrication of PDMS microfluidic devices in the cleanroom, 2. preparation and

seeding of cells in the neuroelectronics lab and 3. imaging of cells using a

lens free microscope.

|

| Some very trendy steel capped shoes |

When you first walk in you can be a little taken aback, the

combination of extra suit and the positive pressure makes moving at first a

little slow. But you get used to it by the time you arrive in the fabrication

area. Both of imec’s cleanrooms are amazing. Tech companies like Dutch ASML,

German Aixtron and American Applied Materials use the class 1000 cleanroom to

develop semiconductor technologies, while the class 1 is used for lower volume fabrication and

production.

To conduct our experiments we need to create PDMS devices with various microchannel designs using a master silicon wafer. From there we cut the devices and adhere them to glass in preparation for imaging. The whole procedure takes more than 24 hours and requires we to suit up about three to four separate times.

To conduct our experiments we need to create PDMS devices with various microchannel designs using a master silicon wafer. From there we cut the devices and adhere them to glass in preparation for imaging. The whole procedure takes more than 24 hours and requires we to suit up about three to four separate times.

While it seems like a hassle, it is really incredible to be

able to use new tools that leaders in the bio and nano-tech industries use, and

in small way contribute to R&D at imec. Plus it’s pretty cool to get up in

the morning, go to work and rock a different kind of suit.

|

| FAB 1-Cleanroom Entry Way |

---Victoria Laney

Monday, June 22, 2015

Something Old, Something New

Hallo from Belgium!

Even just a week here has felt like a lifetime - battling through storms to get here and endless paperwork and training, we’ve finally all settled in and are ready to get our noses to the grindstone!

I’ll be working on two different projects during my time at imec, both of which are part of a larger design concept. The team I’m with is designing a cell-sorting device that can be much smaller and more efficient than the large conventional machines. This device uses lens-free microscopy to distinguish different cell types, which in effect takes the way a cell scatters light and reconstructs it into an image. One of my projects is to use both cultured cancer cells and white blood cells purified from blood to test and verify that the software involved can recognise the different cell types. This involves a lot of cell culture and fluorescent staining, which I’m very familiar with. The facilities at imec for tissue culture are very similar to what we have in my lab back at Hopkins, which has allowed me to dive right in to the work.

The other project I’m less familiar with, though it uses a lot of skills with a microscope that I’ve learned from imaging cells back home. One member of our team designed a bunch of different waveguides (structures etched into a silicon chip that guide a beam of light) to use in the cell-sorting device to focus the light at a specific point to use for the lens-free imaging. Using a fluorescent microscope, I’m testing each design and measuring how efficiently it focuses the light and in what pattern it emits light. Dealing with the waveguide and the laser used as a light source isn’t something I’ve had any experience with, but my two mentors on the project are very supportive and have been incredibly helpful while I’m learning the setup.

One thing that I’m impressed with is the diversity of the team I’m working with - we have a biologist, a physicist, and two software engineers, one of whom functions more as a mechanical engineer on this project. Having so many disciplines come together means that every discussion has very different viewpoints contributing to it, and every problem has solutions proposed from many different angles. Even though I don’t understand all of the technical jargon involved with the waveguide setup, they’re more than willing to break down the information for me so I can understand and contribute to the project myself!

Leuven itself is an absolutely stunning town. Classic European architecture mixes with more modern glass buildings in a way that reflects the atmosphere of the town itself - quaint and quiet, but with a very youthful population. After a week full of training, I spent last weekend relaxing in the city, spending several hours reading in a park and chatting with a few of the local students. I visited the M - Museum Leuven, which had a very varied collection ranging from wall-sized paintings of the Crucifixion to one of the oldest windmill cups in the world (used for a drinking game - blowing into a small pipe started the blades of the decorative windmill to spin, and the aim was to finish the drink in the cup before they stopped spinning.) We’ve wandered around the city centre and tried a few restaurants already, but there’s still plenty more I look forward to seeing in Leuven!

Even just a week here has felt like a lifetime - battling through storms to get here and endless paperwork and training, we’ve finally all settled in and are ready to get our noses to the grindstone!

I’ll be working on two different projects during my time at imec, both of which are part of a larger design concept. The team I’m with is designing a cell-sorting device that can be much smaller and more efficient than the large conventional machines. This device uses lens-free microscopy to distinguish different cell types, which in effect takes the way a cell scatters light and reconstructs it into an image. One of my projects is to use both cultured cancer cells and white blood cells purified from blood to test and verify that the software involved can recognise the different cell types. This involves a lot of cell culture and fluorescent staining, which I’m very familiar with. The facilities at imec for tissue culture are very similar to what we have in my lab back at Hopkins, which has allowed me to dive right in to the work.

The other project I’m less familiar with, though it uses a lot of skills with a microscope that I’ve learned from imaging cells back home. One member of our team designed a bunch of different waveguides (structures etched into a silicon chip that guide a beam of light) to use in the cell-sorting device to focus the light at a specific point to use for the lens-free imaging. Using a fluorescent microscope, I’m testing each design and measuring how efficiently it focuses the light and in what pattern it emits light. Dealing with the waveguide and the laser used as a light source isn’t something I’ve had any experience with, but my two mentors on the project are very supportive and have been incredibly helpful while I’m learning the setup.

One thing that I’m impressed with is the diversity of the team I’m working with - we have a biologist, a physicist, and two software engineers, one of whom functions more as a mechanical engineer on this project. Having so many disciplines come together means that every discussion has very different viewpoints contributing to it, and every problem has solutions proposed from many different angles. Even though I don’t understand all of the technical jargon involved with the waveguide setup, they’re more than willing to break down the information for me so I can understand and contribute to the project myself!

Leuven itself is an absolutely stunning town. Classic European architecture mixes with more modern glass buildings in a way that reflects the atmosphere of the town itself - quaint and quiet, but with a very youthful population. After a week full of training, I spent last weekend relaxing in the city, spending several hours reading in a park and chatting with a few of the local students. I visited the M - Museum Leuven, which had a very varied collection ranging from wall-sized paintings of the Crucifixion to one of the oldest windmill cups in the world (used for a drinking game - blowing into a small pipe started the blades of the decorative windmill to spin, and the aim was to finish the drink in the cup before they stopped spinning.) We’ve wandered around the city centre and tried a few restaurants already, but there’s still plenty more I look forward to seeing in Leuven!

---Rebecca Black

Friday, June 19, 2015

A taste of Leuven

|

| Rachel Bang & Gwen Hoffmann |

The past week and a half has been a whirlwind of exploring, trying new things, training and learning. I’ve enjoyed being in Leuven and working at imec so far. This is my first time coming to Europe, so I wasn’t sure what to expect.

Last weekend I focused on exploring Leuven and the surrounding area. By now, I feel like I have a better idea of how the city is laid out, so I can spend less time staring at maps and more time enjoying the pretty architecture and the laid back atmosphere of Leuven. On Saturday, there was a farmers market in the city center, where I enjoyed a speculoos tart. Speculoos is a spiced shortbread cookie (similar to gingerbread) popular in Belgium and the surrounding area. Other than the farmers market, we went to see the botanical gardens and explored the interior of Universiteitsbibliotheek, which is the central library of the Katholieke Universiteit Leuven (KU Leuven). Inside the library we found spiral staircases, a magnificent reading room, and a small archeological exhibit called “Beyond the Grave”.

On Sunday, I decided to explore the area surrounding Leuven by biking to Park Abbey and Horst Castle. Both were beautiful buildings surrounded by serene lakes and woods. The bike ride to get to these places was enjoyable. The countryside outside of Leuven is mostly rolling hills and farmland. Horst Castle is a medieval castle that was pretty from the outside, but unfortunately fairly empty inside the building.

At imec, I began to learn the procedures I will be using over the next two months after completing all the necessary safety trainings. I will be working on droplet digital polymerase chain reaction (ddPCR). In ddPCR, the PCR reaction mixture is split into many tiny droplets in oil, each containing one or zero strands of DNA to be amplified. Using this method, we can detect DNA fragments at much lower concentrations than is possible with standard qPCR. I learned about PCR in the class Molecules and Cells at Hopkins, but now I am looking forward to gaining a deeper understanding of ddPCR and helping to improve the method!

---Gwen Hoffmann

|

| Speculoos |

|

| Horst Castle |

Settling in

It's been around 10 days since I had arrived in Belgium and I'm really getting the hang of things now. I was lucky in that I arrived here with Gwen (Hoffmann) so we were able to figure out the logistics and administrative details within the first few days together. Wisteria, the dorm I'm staying at, is super nice; since I'm in the studio, I have my own bathroom and kitchen in it (a big upgrade from my freshman dorm). But, even with my own stove and oven, I find myself going to the common kitchen occasionally to meet with the other people - students from other countries like the Netherlands, India, and Germany - who are also working at IMEC.

There are two things that are noticeably different here in Belgium. First, people bike everywhere! I went into the City Centre in Leuven, which is incredibly gorgeous, and it was the first time I've ever seen that many bikes at once. Luckily, everything is close together (all the necessary stores and shops are easily within 10 km) so riding a bike is actually a really nice change in pace from driving. The other thing I've noticed is the sun sets at 10:30 p.m. and rises way before 6 a.m. Because of this, the first day I wasn't able to sleep in as the sun came and woke me up bright and early at 5:30 in the morning.

At IMEC, I'm working on microfluidic, digital droplet PCR (ddPCR). Like qPCR, it amplifies the DNA to exponentially greater volumes in a relatively short amount of time. Unlike qPCR, amplification is done in tiny droplets which makes the entire process a lot faster. The project itself is very different from what I'm learning at Hopkins, so I had to spend some time reading articles and figuring out the general process, but I've learned a lot over the past 10 days! My mentor, Rodrigo, is wonderful and super helpful and the topic itself is really interesting, so I'm expecting many fun days during my stay here.

---Rachel Bang

There are two things that are noticeably different here in Belgium. First, people bike everywhere! I went into the City Centre in Leuven, which is incredibly gorgeous, and it was the first time I've ever seen that many bikes at once. Luckily, everything is close together (all the necessary stores and shops are easily within 10 km) so riding a bike is actually a really nice change in pace from driving. The other thing I've noticed is the sun sets at 10:30 p.m. and rises way before 6 a.m. Because of this, the first day I wasn't able to sleep in as the sun came and woke me up bright and early at 5:30 in the morning.

At IMEC, I'm working on microfluidic, digital droplet PCR (ddPCR). Like qPCR, it amplifies the DNA to exponentially greater volumes in a relatively short amount of time. Unlike qPCR, amplification is done in tiny droplets which makes the entire process a lot faster. The project itself is very different from what I'm learning at Hopkins, so I had to spend some time reading articles and figuring out the general process, but I've learned a lot over the past 10 days! My mentor, Rodrigo, is wonderful and super helpful and the topic itself is really interesting, so I'm expecting many fun days during my stay here.

---Rachel Bang

Wednesday, June 17, 2015

New interns arrive at IMEC headquarters for summer research

Each summer, Johns Hopkins Institute for NanoBioTechnology (INBT) has funding to support research internships abroad. The International Research Experience for Students (IRES) program, funded by the National Science Foundation, provides support for students to work with researchers at The Inter-University MircroElectronics Centre (IMEC) in Leuven, Belgium. Students work at IMEC’s world-class microfabrication facility and learn to design, fabricate and test a wide range of biomedical devices.

|

| Rachel Bang |

Over the next several weeks, each student will blog about their experiences both as researchers in an international laboratory, but also as a visitor to Europe. Expect to see some lab photos and some tourist trip photos.

For 2015, four students have arrived in Belgium. They include Rachel Bang, Sophomore in Mechanical Engineering; Rebecca Black, Junior in Molecular and Cell Biology; Gwendolyn Hoffmann, Senior in Materials Science and Engineering; and Victoria Laney, Senior on Chemical and Biomolecular Engineering. For more information about the IRES program through INBT, visit http://inbt.jhu.edu/

All press inquiries about this program or about INBT in general should be directed to Mary Spiro, INBT's science writer and media relations director at mspiroATjhu.edu. For information about INBT's collaboration with IMEC, contact INBT's director of corporate partnerships, Tom Fekete at tfekete1ATjhu.edu

Subscribe to:

Posts (Atom)